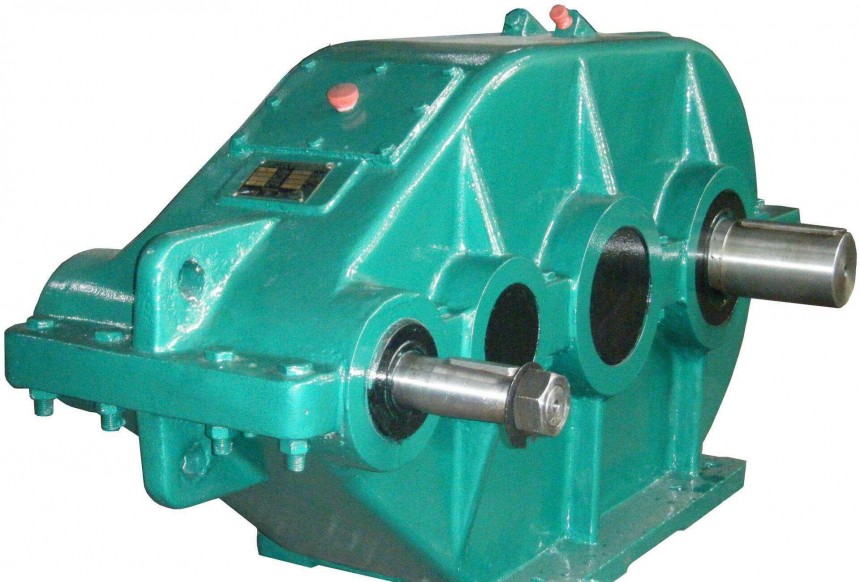

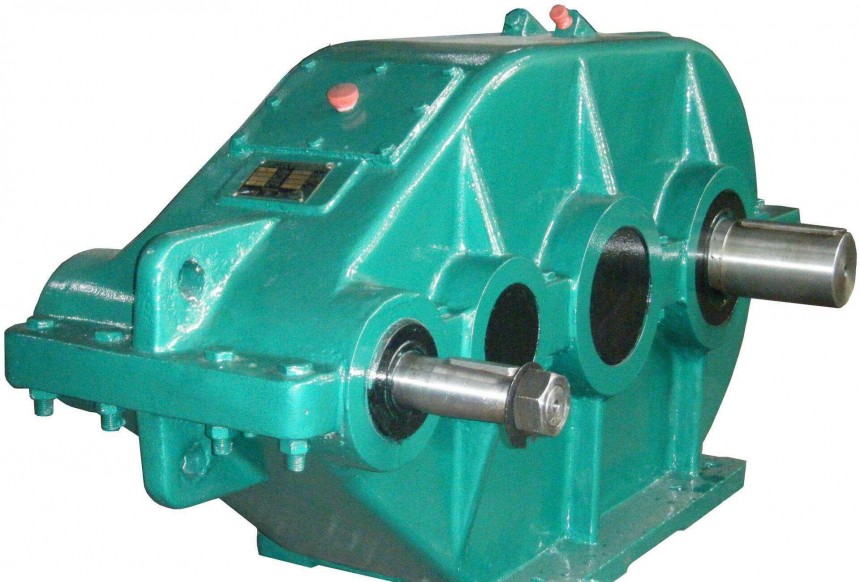

During the use of the

ZSC gearbox, it is inevitable that malfunctions may occur. If problems arise, it is necessary to disassemble the gearbox equipment. In order to better use the ZSC gearbox, the following are the disassembly steps for the ZSC gearbox:

1. First, let's disassemble the upper housing of the ZSC gearbox. If the ZSC gearbox has a half coupling, remove the half coupling first. Afterwards, remove the fixing bolts and screw the nuts onto the bolts for proper storage. Check for any damage or cracks in the upper shell. Make assembly marks and remove the bearing end cover. First, check for any missing bolts or other abnormal situations. Once everything is normal, use a top screw to lift the upper shell and place it on the prepared pad for easy assembly and use in the future.

Measure the clearance between each bearing using a feeler gauge or pressure lead wire method. Multiple points should be measured for each set of bearings and relevant records should be kept. Drain the lubricating oil from the ZSC gearbox and store it in a dedicated oil drum.

2. Lift out the driving shaft and driven shaft assembly. Mark the meshing area of the gears. After lifting out, place each gear assembly on a wooden board neatly and stably, be careful not to damage the equipment, and disassemble the bearings and gears.

3. Clean the bearings, housing, and gears with kerosene to prepare for subsequent inspections.

Through the above introduction, everyone should have a simple understanding of the disassembly steps of ZSC gearbox. Manufacturer's reminder: When using ZSC gearboxs in daily life, we should regularly conduct maintenance work on the equipment to ensure that it can perform at its normal level in the later stage. If you happen to need gear reducer equipment, you can call us. We are quite professional in the gear reducer industry.

Address:Zibo, Shandong

Address:Zibo, Shandong WhatsApp:+8615805335335

WhatsApp:+8615805335335 Wechat: +8615805335335

Wechat: +8615805335335  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com