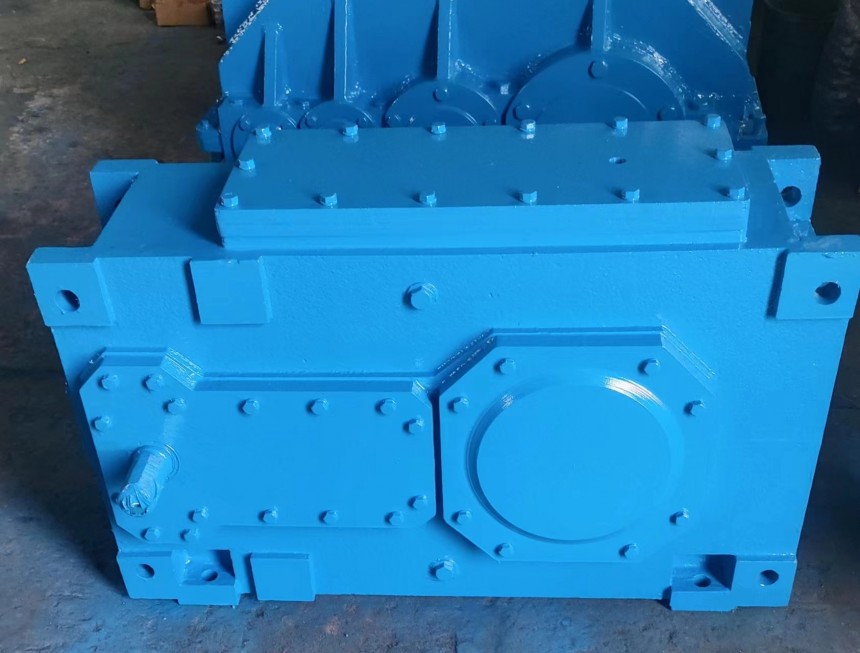

How is shredder reducer polished?Polishing is an important process in the production of shredder reducers,which determines the quality of the machine.Therefore,it is necessary for us to follow the

shredder reducer factory to familiarize ourselves with polishing knowledge.

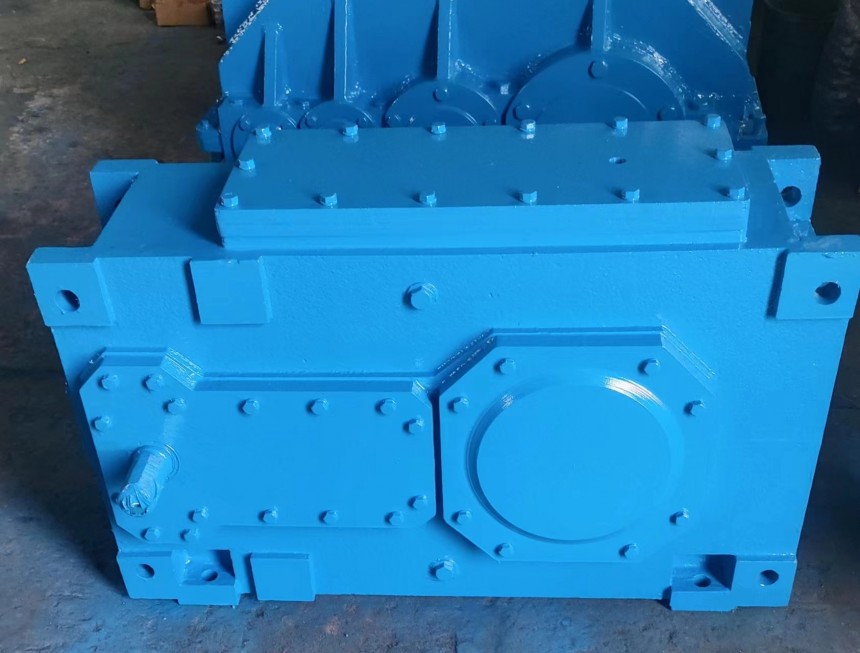

1.Flame polishing:Using flames to soften and bake the surface of shredder reducers,with thermal impact,can remove some diagonal lines and wrinkles on the surface.Many cutting edges are subjected to flame polishing,but this treatment method will reduce the flatness of the shredder reducer surface.

2.Polishing with polishing powder:This method involves high-speed friction on the surface of the machine to remove scratches.Before polishing,the polished area must be sanded with a sand belt.This method uses many materials,and the best effect is cerium oxide,but the process speed is relatively slow.

3.Acid treatment polishing:Using the corrosive effect of acid on the surface of shredder reducers for surface treatment.Before polishing shredder reducers,it is also necessary to use sand belts for polishing,because acid polishing will greatly reduce the thickness of the equipment itself and may not completely remove the surface patterns.

I hope everyone can take it seriously and do a good job in polishing the shredder reducer,so as not to affect the future use effect and efficiency.

Address:Zibo, Shandong

Address:Zibo, Shandong WhatsApp:+8615805335335

WhatsApp:+8615805335335 Wechat: +8615805335335

Wechat: +8615805335335  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com