When designing non standard gearbox,manufacturers are quite particular.They have designed various models of equipment according to the different usage needs of different industries.The use of non standard gearbox is still quite common,and many people are not very familiar with the meaning of each level of equipment.In order to better use our equipment,it is necessary to understand its levels.Below,we will briefly understand:

In fact,a pair of meshing gears is called primary transmission.Primary transmission is achieved through one reduction,while two-stage transmission is achieved through two reductions.If it is a regular gearbox,it is generally achieved through two-stage reduction.When manufacturers design single-stage reducers,they are usually used for specialized equipment such as papermaking,and there are certain requirements for their speed ratios.Generally,a speed ratio of 6-20 is achieved through two-stage transmission,20-90 is achieved through three-stage transmission,90-500 is achieved through two-stage transmission,and non standard gearbox with a speed ratio above 87 are achieved through two-stage transmission.

Based on the introduction of various stages of non standard gearbox above,I hope everyone can have a better understanding of them.If there are any problems in the later stage,it can be helpful to everyone.In order to maintain a stable operating state of the equipment for a long time,regular maintenance and repair work is essential.Therefore,it requires the equipment operator to pay more attention to observing its operating status during the use of the equipment.Once problems occur,they should be resolved in a timely manner to avoid affecting the normal use of the equipment. Address:Zibo, Shandong

Address:Zibo, Shandong WhatsApp:+8615805335335

WhatsApp:+8615805335335 Wechat: +8615805335335

Wechat: +8615805335335  E-mail:zs@sdsmachinery.com

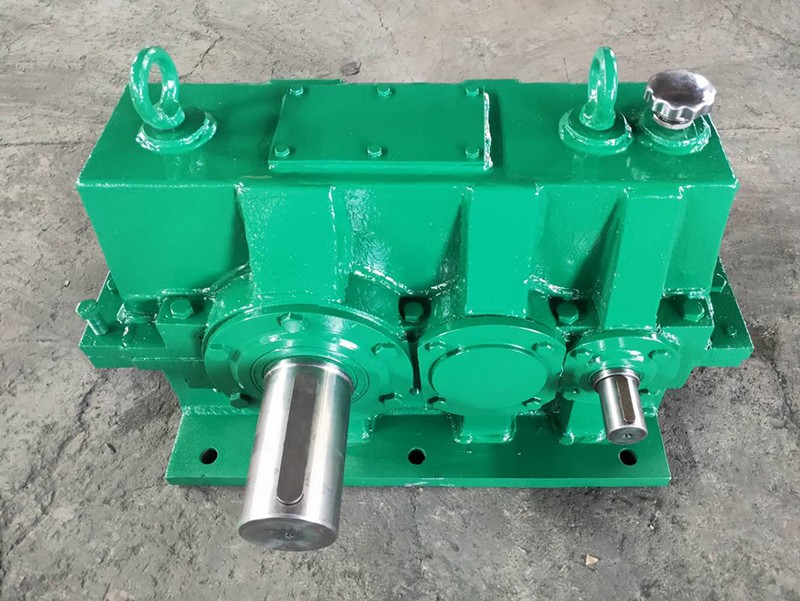

E-mail:zs@sdsmachinery.comHard tooth surface reducer manufacturer: The company produces various types and specifications of reducers such as ZQ reducers, shredder reducers, MBY edge drive grinder reducers, HB high-power reducers, etc