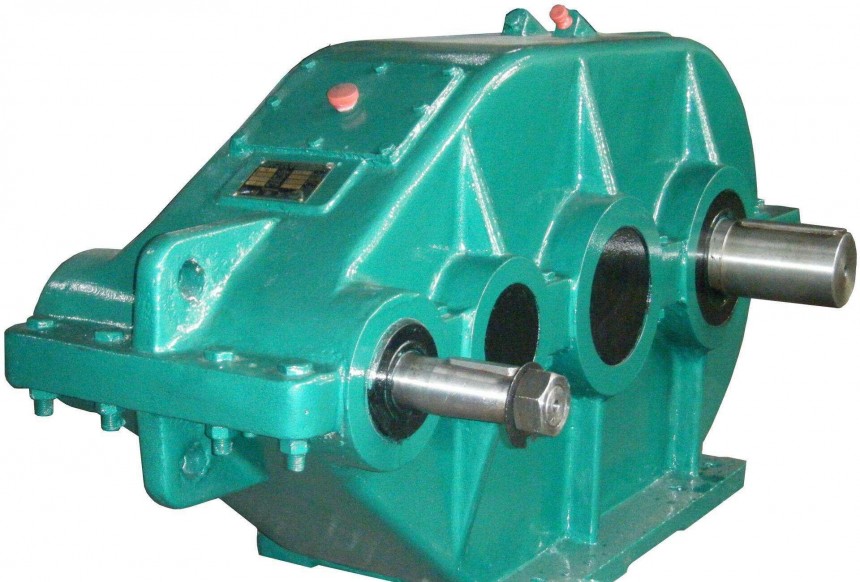

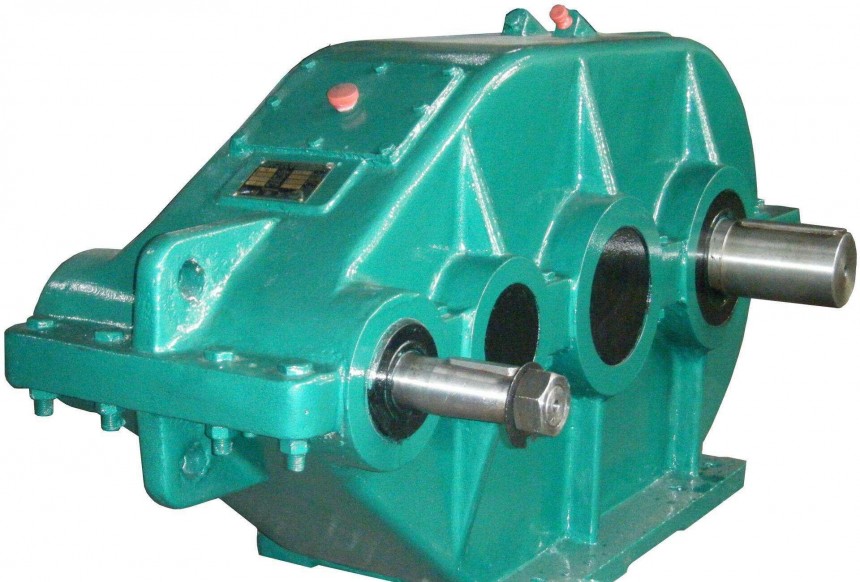

What are the main components of ZSC gearbox? We need to have a clear understanding of it in order to better utilize it.

The structural type of ZSC gearbox is a two-stage three-axis cylindrical helical gear horizontally divided fully enclosed type. Lubricating oil is stored inside the reducer, with oil blocking plates installed on the drive shaft and intermediate shaft. Rolling bearings are used for each shaft fulcrum, and the axial clearance can be adjusted with an internal adjustment ring. It has strong universality and interchangeability, simple maintenance, and an efficiency coefficient of 0.94. It has the advantages of low starting resistance and flexible movement. The upper part of the machine has an inspection cover, and the lower part has an oil gauge pointer and an oil plug for draining waste oil. The gear transmission of JZSC gearbox has a circumferential speed not exceeding 12m/s, a high-speed shaft speed not exceeding 1500r/min, and a working environment temperature of -40 ℃ -+40 ℃. The reducer is used for both forward and reverse operation. The gears and shafts are made of high-quality carbon steel and undergo quenching and tempering treatment. The gears are mostly made of high-grade cast steel and undergo normalizing treatment. The housing material is gray cast iron HT-200 and has undergone aging treatment. The gears are manufactured with 8th level precision and have roll cut helical teeth with a tilt angle of 8 ° 6'34 ". The total number of teeth in the two pairs of teeth is 99 teeth.

We have a brief understanding of the main components of the ZSC gearbox. We hope that the knowledge brought by the

ZSC gearbox manufacturer can be convenient and more conducive to everyone's use.

Address:Zibo, Shandong

Address:Zibo, Shandong WhatsApp:+8615805335335

WhatsApp:+8615805335335 Wechat: +8615805335335

Wechat: +8615805335335  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com