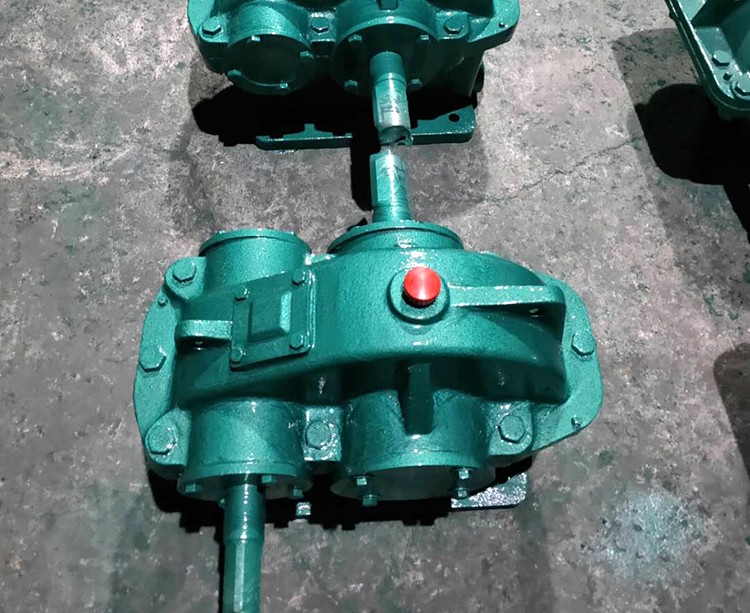

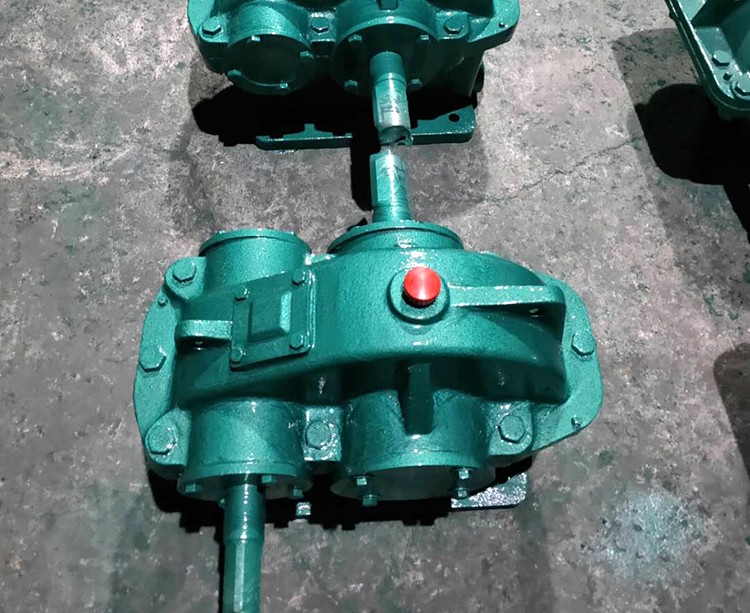

When the soft tooth surface reducer is regularly inspected and maintained,and when

China soft tooth surface reducer manufacturer repair equipment failures,in some cases,the equipment needs to be disassembled for inspection and maintenance.This requires memorizing the disassembly method.

1.Firstly,remove the protective covers of each part,motor,and brake disassembly lines.Pay attention to marking the disassembly lines as a reference for reassembly.

2.Disassemble the pin of the high-speed shaft coupling of the soft tooth surface reducer,loosen the low-speed shaft gear coupling,and move the two halves of the coupling away to both sides.Before disassembling the high and low-speed shaft couplings of the reducer,it is necessary to mark the relative position with a flat shovel or sample punch as the basis for reinstalling the coupling.

3.Remove the anchor bolts of the motor and lift off the motor.When disassembling the motor anchor bolts,record the original thickness and position of the anchor gasket as a basis for alignment.Release the brake anchor bolts,remove the brake adjustment screw,disassemble the brake,and remove the brake.

4.Remove the reducer backstop and place it in the designated position to avoid collision.

5.Mark the relative position of the upper and lower joint surfaces of the reducer,remove the fastening bolts of the upper and lower cover joint surfaces of the reducer,replace damaged bolts,and remove the locating pin.To check for any missing or cracked bolts,screw the nut onto the screw and store it properly.

6.Mark the assembly of each bearing end cover,remove the fastening bolts of the bearing end cover,remove the end cover,measure the thickness and number of asbestos gaskets on the bearing end cover with an external micrometer,and make original records.Preliminary inspection of the bearing end cover shows no wear or cracks on the straight end face.

7.Before lifting the upper cover,it should be checked for any missing screws or other abnormal phenomena(use a top screw to lift the upper cover,lift it onto the prepared pad,and operate the crane with a certificate).Special attention:Please mark the original meshing position of the gears and mesh them in the original order when reinstalling.

Attention:When disassembling the soft tooth surface reducer,it is necessary to strictly follow the order to avoid collision.It is also important to place the corresponding components in the designated positions to prevent incorrect,insufficient,or lost assembly.

Do you have a clear understanding of the disassembly method for soft tooth surface reducers based on the above instructions compiled by the editor?After learning about it,you need to put it into practice.You may encounter other problems,so remember to contact us for consultation later.

Address:Zibo, Shandong

Address:Zibo, Shandong WhatsApp:+8615805335335

WhatsApp:+8615805335335 Wechat: +8615805335335

Wechat: +8615805335335  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.com