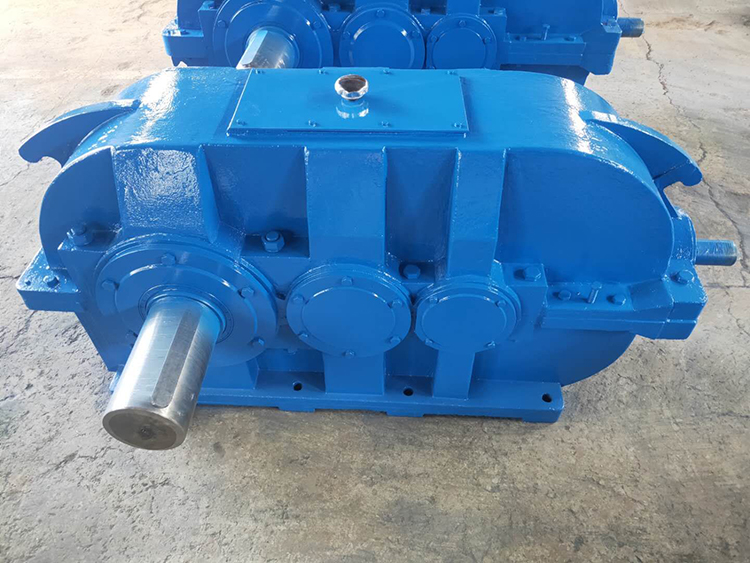

DCY three-stage transmission conical cylindrical gear reducer

Cone cylindrical gear reducer (hereinafter referred to as reducer) is a transmission device used for arranging the input shaft and output shaft in a vertical direction. Mainly used for belt conveyors and various transportation machinery, it can also be used in the transmission mechanism of various general machinery such as coal, metallurgy, mining, chemical, building materials, light industry, petroleum, etc.

DCY160、DCY180、DCY200、DCY224、DCY350、DCY280、DCY315、DCY355、DCY400、DCY450、DCY500、DCY560、DCY630、DCY710、DCY800

The speed ratios are 16, 18, 20, 22.4, 25, 28, 31.5, 35.5, 40, 45, 50

1、 The purpose, performance characteristics, and model markings of the gearbox

1.1 Purpose

Cone cylindrical gear reducer (hereinafter referred to as reducer) is a transmission device used for arranging the input shaft and output shaft in a vertical direction. Mainly used for belt conveyors and various transportation machinery, it can also be used in the transmission mechanism of various general machinery such as coal, metallurgy, mining, chemical, building materials, light industry, petroleum, etc.

1.2 Performance Characteristics

High load-bearing capacity, low noise, small size, light weight, high efficiency, and long service life.

1.3 Parameter Range

DBY, DBYK, and DBZ reducers each have 12 specifications, with nominal center distances of 1601802002242502803153554004450500560mm. Each specification has 5 transmission ratios (8, 10, 11.2, 12.5, 14), 2 rotation directions, and 4 assembly types, forming 240 types of reducers.

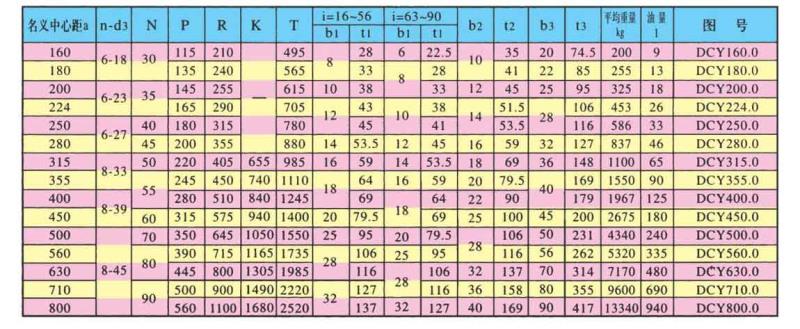

There are 15 specifications of DCY, DCYK, and DCZ reducers, with nominal center distances of 1601802002242502803153554004050560630710800mm; Each specification has 11 transmission ratios (16, 18, 20, 22.4, 25, 28, 31.5, 35.5, 40, 45, 50), two rotation directions, and four assembly types, forming 660 types of reducers.

This reducer series can meet the power requirements of TD and DX belt conveyors and other transportation machinery within a working range of 0.8-6.5m/s belt speed.

1.4 Structure

Lubrication of gearbox: In general, the gears and bearings of the gearbox are lubricated by splashing oil in a pool and cooled naturally. Only when the working balance temperature of the reducer exceeds the specified value, or the carrying power exceeds the thermal power PG1, can the oil pool lubrication with cooling pipes be used.

1.5 Model and Marking

The model of the reducer consists of a type code, nominal center distance a (final center distance), nominal transmission ratio, assembly type code, and input shaft rotation direction code.

D-belt conveyor group code, B-two-stage transmission, C-three-stage transmission, Y-hard tooth gear, Z-medium hard tooth gear, K-output shaft in hollow shaft form.

Nominal center distance: expressed in actual numbers, in millimeters

Transmission ratio: expressed in nominal transmission ratio.

Assembly type: represented by Roman numerals I, II, III, and IV.

Rotation direction of input shaft: When facing the direction of the input shaft, S is clockwise and N is counterclockwise.

Example of Marking:

The nominal center distance is 280mm, the nominal transmission ratio is 31.5, the assembly type is type III, and the input shaft is a three-stage transmission reducer that rotates clockwise. The marking of the reducer is DCY280-31.5-III S

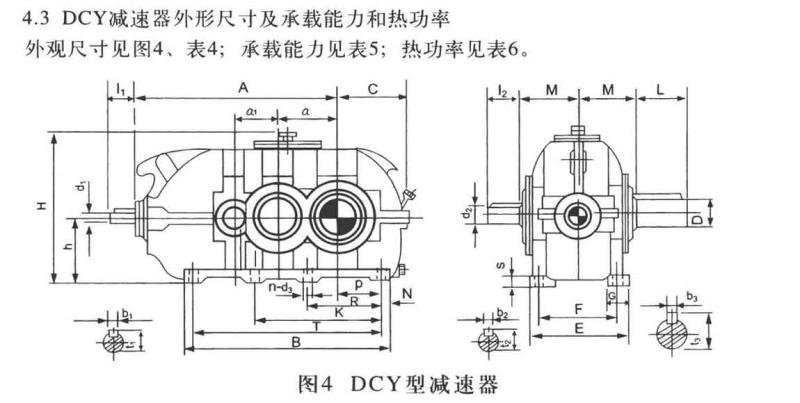

The installation dimensions of DCY reducer are shown in the following table

Address:Zibo, Shandong

Address:Zibo, Shandong WhatsApp:+8615805335335

WhatsApp:+8615805335335 Wechat: +8615805335335

Wechat: +8615805335335  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.comHard tooth surface reducer manufacturer: The company produces various types and specifications of reducers such as ZQ reducers, shredder reducers, MBY edge drive grinder reducers, HB high-power reducers, etc