The principle of non-standard reducer: the purpose of reducing speed through the use of various levels of gear transmission. Non standard reducers are composed of gear pairs at all levels. For example, gears can be driven by small gears to achieve deceleration, and then pass through multiple stages of this structure, which can greatly reduce speed and increase torque.

The specific explanation of the principle of non-standard reducer: When the output speed of the motor is input from the drive shaft, the small gear rotates, and the small gear drives the large gear to move. The gears of the large gear are larger than those of the small gear, and the speed of the large gear is slower than that of the small gear. It is output by the shaft (output shaft) of the large gear, which is used to output deceleration.

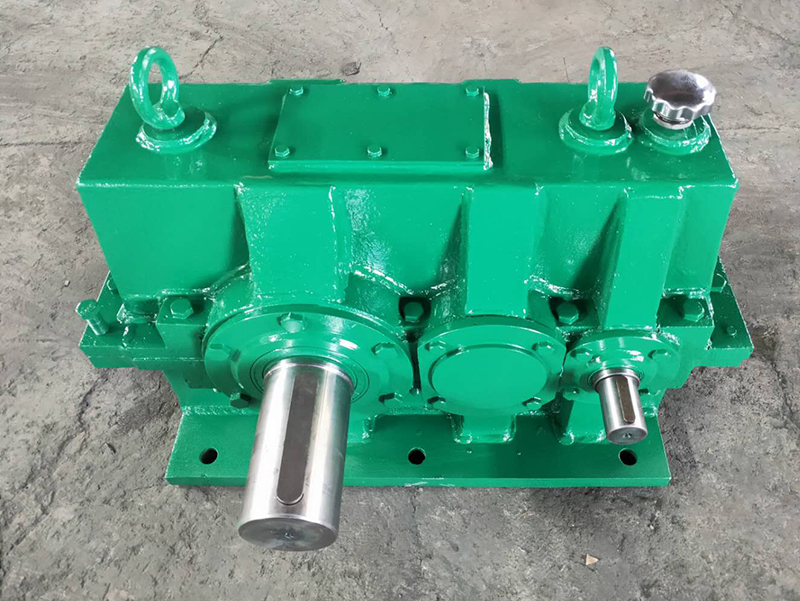

Non standard reducers are generally used for low-speed and high torque transmission equipment. Electric motors, internal combustion engines, or other high-speed power are transmitted through gears on the input shaft of non-standard reducers, causing the large gears on the output shaft to mesh and achieve the purpose of deceleration. The non-standard reducer will also have several pairs of identical main gears to achieve the desired reduction effect.

Address:Zibo, Shandong

Address:Zibo, Shandong WhatsApp:+8615805335335

WhatsApp:+8615805335335 Wechat: +8615805335335

Wechat: +8615805335335  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.comHard tooth surface reducer manufacturer: The company produces various types and specifications of reducers such as ZQ reducers, shredder reducers, MBY edge drive grinder reducers, HB high-power reducers, etc