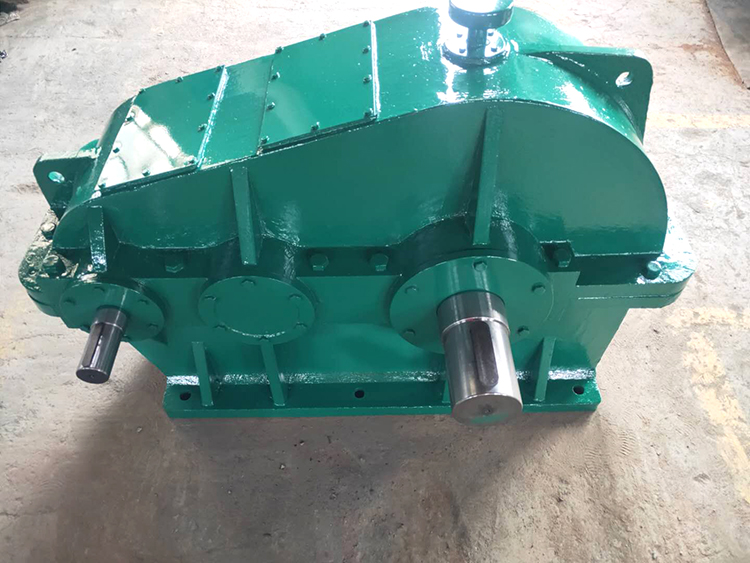

The gears of ZL series reducers are processed by carburizing, quenching, and grinding, with high load-bearing capacity and low noise; Mainly used for belt conveyors and various transportation machinery, it can also be used in the transmission mechanism of other general machinery. It has the advantages of high load-bearing capacity, long service life, small size, high efficiency, and light weight, and is used in transmission devices where the input shaft and output shaft are arranged vertically.

matters needing attention:

(1) Mark the relative position of the upper and lower joint surfaces of the reducer, remove the fastening bolts of the upper and lower cover joint surfaces of the reducer, replace damaged bolts, and remove the locating pin. Check for any missing or cracked bolts, screw the nut onto the screw and store it properly.

(2) Mark the assembly of each bearing end cover, remove the fastening bolts of the bearing end cover, remove the end cover, measure the thickness and number of asbestos gaskets on the bearing end cover with an external micrometer, and make original records. Preliminary inspection of the bearing end cover shows no wear or cracks on the end face of the stopper.

(3) Before lifting the top cover, check for any missing screws or other abnormal phenomena (use a top screw to lift the top cover, lift it onto the prepared pad, and operate the crane with a certificate). Special attention: The original meshing position of the gear should be marked, and when reinstalling, it should be meshed in the original order.

(4) Dismantle the protective covers of various parts, as well as the disassembly lines of the motor and brake. Pay attention to marking the disassembly lines as a reference for reassembly.

(5) Disassemble the pin of the high-speed shaft coupling of the reducer, loosen the low-speed shaft gear coupling, and move the two halves of the coupling away to both sides. Before disassembling the high and low-speed shaft couplings of the reducer, use a flat shovel or sample punch to mark the relative position as the basis for reinstalling the coupling.

(6) Remove the anchor bolts of the motor and lift off the motor. When disassembling the motor anchor bolts, record the original thickness and position of the anchor gasket as a basis for alignment. Release the brake anchor bolts, remove the brake adjustment screw, disassemble the brake, and remove the brake. Remove the reducer backstop and place it in the designated position to avoid collision.

Address:Zibo, Shandong

Address:Zibo, Shandong WhatsApp:+8615805335335

WhatsApp:+8615805335335 Wechat: +8615805335335

Wechat: +8615805335335  E-mail:zs@sdsmachinery.com

E-mail:zs@sdsmachinery.comHard tooth surface reducer manufacturer: The company produces various types and specifications of reducers such as ZQ reducers, shredder reducers, MBY edge drive grinder reducers, HB high-power reducers, etc